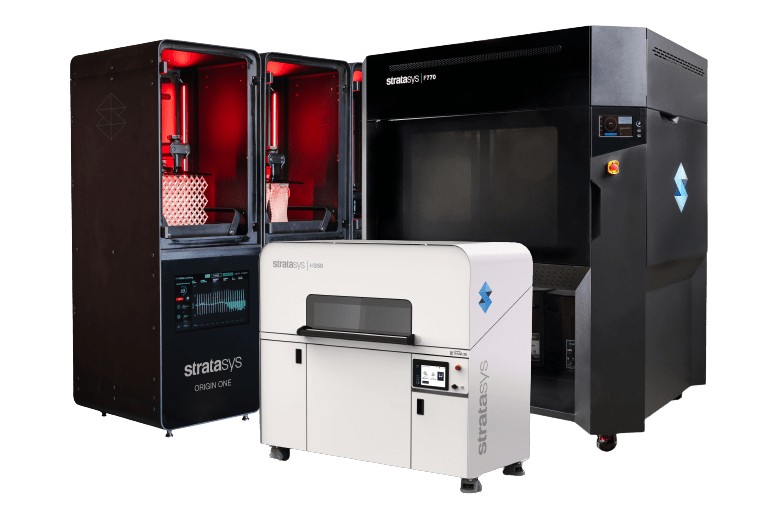

Best Industrial-Grade Solutions.

Why Complicate? Simplify.

Core Offerings

3D printing systems for every application.

Versatile & handy 3D Scanners.

Complete 3D Services for all your needs.

Efficient Systems

Seamless Production

Proprietary Materials

Higher ROI & Profitability

Partner with us

enquiry@arkinfo.in